In the realm of industrial operations, there comes a time when shutdowns or turnarounds become inevitable. Whether it’s for maintenance, repairs, or upgrades, these scheduled shutdowns are critical to ensuring the long-term efficiency, safety, and profitability of industrial facilities. Here we will explore the unique role of industrial shutdown services and how they contribute to maximizing efficiency and minimizing downtime during these critical periods.

Comprehensive Planning and Strategy:

Industrial shutdown services play a pivotal role in the meticulous planning and development of strategies for shutdowns or turnarounds. They bring a wealth of experience and industry knowledge to the table, collaborating closely with facility owners, project managers, and other stakeholders. By thoroughly understanding the operational requirements, budgetary constraints, and timeline considerations, they create a customized roadmap that encompasses every facet of the shutdown process.

Precise Scheduling and Resource Management:

One of the key challenges during an industrial shutdown is to minimize downtime while maximizing resource utilization. Shutdown services excel in developing precise schedules that optimize the allocation of resources such as labor, equipment, and materials. They strategically sequence tasks, ensuring seamless coordination and smooth transitions between different phases of the shutdown. This meticulous planning helps in reducing overall downtime and minimizing disruption to ongoing operations.

Safety Compliance and Risk Mitigation:

Industrial shutdowns involve a myriad of complex tasks, often requiring specialized equipment and expertise. Safety and risk management are of paramount importance to safeguard both the personnel involved and the facility itself. Shutdown services diligently assess potential risks, implement stringent safety protocols, and adhere to relevant regulations and industry standards. Their experience in handling hazardous materials, confined spaces, and high-risk environments ensures a secure working environment during the shutdown process.

Streamlined Execution and Project Management:

During a shutdown, time is of the essence, and efficient execution is crucial. Industrial shutdown services possess the necessary project management skills to oversee every aspect of the shutdown, from coordinating labor teams to tracking progress and ensuring adherence to schedules. They implement robust communication channels and employ advanced technologies to monitor and report real-time updates. By closely managing tasks and promptly addressing any unforeseen challenges, they minimize delays and keep the project on track.

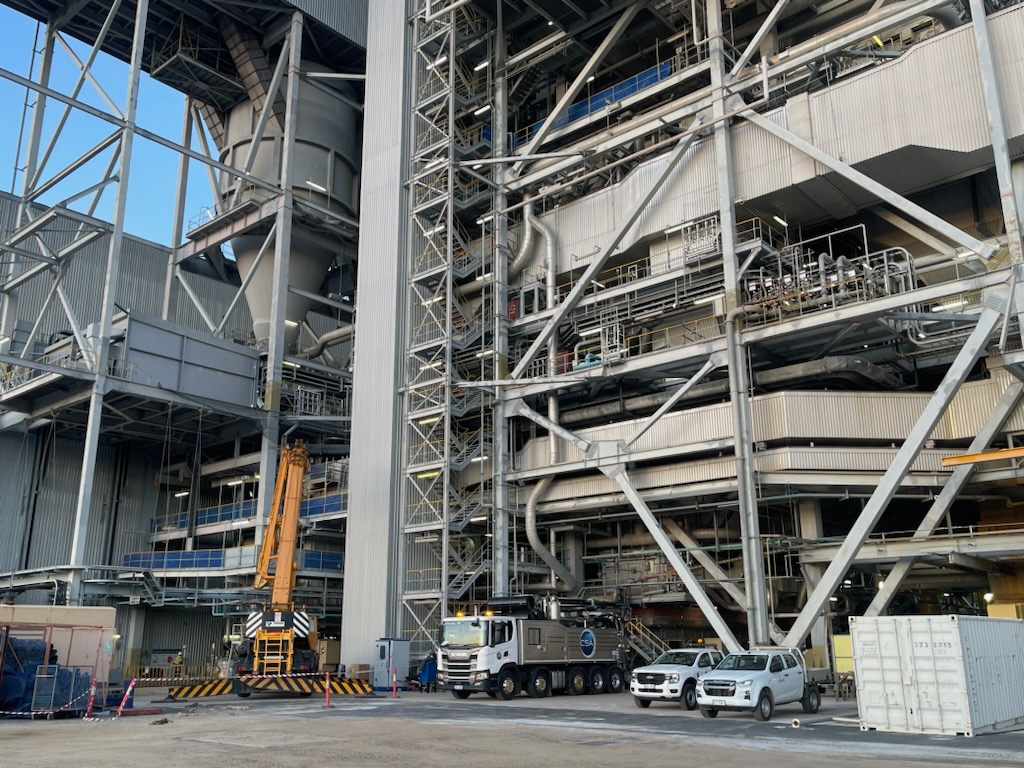

We recently provided shutdown services to one of Queensland’s most significant manufacturing sectors, delivering boiler cleaning and vacuum loading.

At CSA, we recognise the critical role of responsible environmental management and long-term sustainability in the manufacturing industry. Our commitment to environmental preservation extends to our shutdown services. We work closely with our clients to ensure that our industrial waste management services have a minimal negative impact on the surrounding environment and promote long-term sustainability.

Please don’t hesitate to contact CSA today. Our team will collaborate with you to develop a tailored solution that meets your unique requirements while maintaining the highest levels of quality and safety throughout the process.